Why Polythene Sheets Are Essential for Packaging in the UAE

The UAE's scorching heat and humidity demand packaging that can withstand harsh conditions. Polythene sheets rise to the challenge, offering a handy and reliable solution. These versatile sheets act like protective shields, safeguarding your products during storage and transportation. They're also incredibly cost-effective, making them a champion choice for businesses across the UAE.

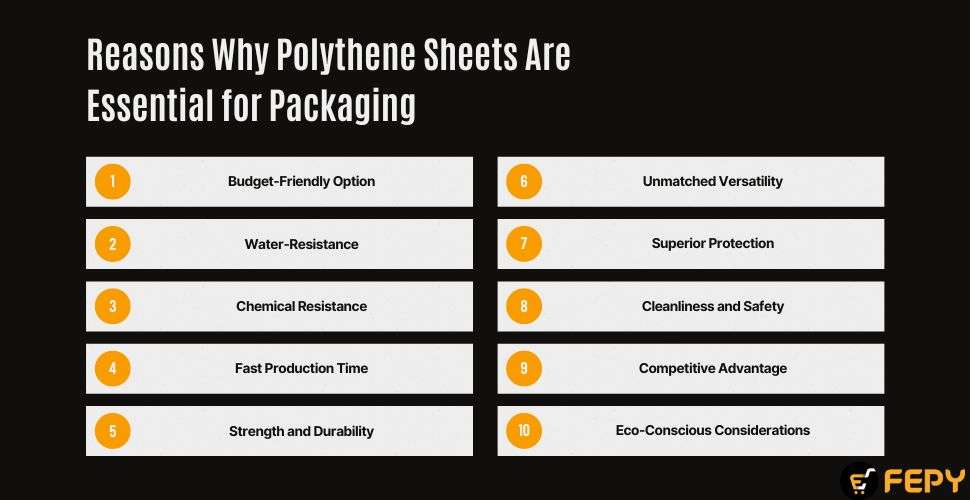

11 Reasons Why Polythene Sheets Are Essential for Packaging in the UAE

- Budget-Friendly Option

- Water-Resistance

- Chemical Resistance

- Fast Production Time

- Strength and Durability

- Unmatched Versatility

- Superior Protection

- Cleanliness and Safety

- Competitive Advantage

- Eco-Conscious Considerations

- Multiple Use

Let's discuss these in detail.

1. Budget-Friendly Option

The cost-effectiveness of polythene is unmatched by any other material.

A significant advantage of this material is that it is significantly cheaper to produce than other materials.

A paper bag might cost you much less, while a polythene sheet of similar size can be available for a fraction of the price of a paper bag. Those savings multiply quickly, especially for high-volume operations.

You can get even better deals if you find the right supplier.

2. Water-Resistance

The water-resistant nature of polythene makes it a super material.

This hydrophobic quality makes it ideal for situations where moisture protection is crucial.

You no longer have to worry about unexpected downpours or spills ruining your products. You can get the best quality Tarpaulin to solve your purpose.

For bulk packaging, polythene sheets are the clear winner in cost comparison.

Additionally, if cost-cutting is a priority, partnering with the right supplier can help your company save significantly on polythene sheets.

ALSO READ: How to Apply Waterproof Concrete in the UAE [Step-by-Step Guide]

3. Chemical Resistance

With Polythene Sheets, you can be worry-free from chemical concerns.

Polythene sheeting boasts surprising resistance to various chemicals, including acids, alkalis, and oils.

This exceptional resistance keeps your sheets solid and intact, even when they come into contact with substances.

The durability of polythene makes it ideal for storing and transporting chemicals.

4. Fast Production Time

Another advantage of using poly packaging bags for your products is the fast production process.

Poly sheeting allows for quick cutting, stretching, and sealing, no matter what size or design you need.

This streamlined process eliminates lengthy waits for custom orders. Some suppliers can deliver them in under four weeks.

5. Strength and Durability

Despite their thinness, polythene sheets have surprisingly high strength for such a thin material.

They come in a range of strengths, with HDPE (High-Density Polyethylene) and MDPE (Medium-Density Polyethylene) taking the top spot for durability.

These heavy-duty choices safeguard your sharp or bulky items from bumps and scrapes.

The thicker the sheet (measured in mils), the stronger its resistance to punctures and tears.

It makes polythene ideal for products requiring extra protection against moisture and other environmental threats.

Food and electronics, for example, can be easily damaged without proper packaging, and polythene sheets come to the rescue.

6. Unmatched Versatility

Polythene sheets are the ultimate champions of customization.

Transform them into brand extensions by incorporating your logos, fonts, and colours. You can display your brand identity on them like a blank canvas.

You can also enhance functionality with a variety of sealing and handling options.

If you need a specific look or feel, you can have polythene in transparent, coloured, or textured forms to match your company's needs.

7. Superior Protection

Polythene offers more than just essential waterproofing.

It's also leakproof, preventing even tiny water vapour molecules from passing through.

Additionally, you can heat-seal this material, creating an airtight barrier around your products.

Polythene offers the advantage of protecting delicate electronic components from moisture, dust, and even tampering. That is why electronics manufacturers rely so heavily on it.

8. Cleanliness and Safety

Many industries place a high priority on safety and cleanliness, and polythene excels at both.

You can see it everywhere, from food and beverages to personal care products and healthcare supplies.

Product developers love its versatility, durability, and resistance to impact, chemicals, and moisture.

The best part is that it inhibits bacterial growth, so you can be confident your products are in good hands.

9. Competitive Advantage

Plastic is becoming increasingly prevalent in the food, personal care, and cosmetics industries. It's a game-changer for products that can be tricky to handle or use, like lotions and liquids.

You can create resealable, reusable containers from plastic that facilitate the smooth dispensing of products. Moreover, it is durable, flexible, and has excellent barrier properties.

Unsurprisingly, product developers use it from shampoo bottles to lotion tubes, pouches, and even over-the-counter medicines.

Polythene ensures your products travel safely from factory to store shelf and, finally, into the happy hands of your customers.

10. Eco-Conscious Considerations

While polythene's usefulness is undeniable, there are valid concerns about its production, use, and disposal.

Most polythene is made from non-renewable materials and can release greenhouse gases when incinerated.

However, it is possible to minimise the impact by utilising biodegradable options, recycling used polythene (around 30% currently gets recycled), using thinner sheets, and disposing of it properly.

Remember, polythene can be a responsible choice if you use it where recycling facilities are available.

11. Multiple Use

Polythene sheets are the ultimate utility players. They excel at wrapping and protecting anything from furniture to electronics during storage or transport, acting as a shield against moisture, dust, and other unwelcome elements.

In agriculture, they protect crops, warm soil, and cover greenhouses. You can even use them to shield young plants from frost or create a warm environment for them to grow in.

We must remember to mention the construction industry as well. Polythene sheet's durability and waterproofing abilities make it ideal for damp-proofing walls and floors and creating temporary roofs during projects. It's a true multitasker that protects things from the elements.

FAQs

Q. What is the purpose of a polythene sheet?

Polythene sheets are multi-talented players in the packaging world. Their primary function is safeguarding your products from moisture, dust, and other environmental threats during storage and transport. They act as a protective shield, ensuring your products arrive at their destination safe and sound.

Q. What is poly packaging?

Poly packaging is a broad term encompassing packaging made from polyethylene, a type of plastic. Polythene sheets are a popular form of poly packaging, but other options include poly bags, tubes, and pouches.

Q. Why is polypropylene used in packaging?

Manufacturers sometimes use polypropylene in packaging, typically making polythene sheets from polyethylene. Polyethylene's popularity stems from its strength, flexibility, waterproof nature, and relatively low production cost.

Q. What is the difference between plastic sheeting and polyethylene sheeting?

Plastic sheeting is a general term that encompasses many different plastic film types, including polyethylene. So, all polyethylene sheeting is plastic sheet, but not all plastic sheets are polyethylene. Other plastic film types are used for various purposes and may have properties different from polyethylene.

Final Words

Polythene sheets are a true game-changer in the world of packaging! They're budget-friendly, tough as nails, and endlessly versatile, making them a favourite choice for businesses across the UAE.

The best part is that you can get top-quality Polythene Sheets from FEPY. It is the UAE's leading e-commerce platform for construction materials.

It is, therefore, essential to consider the power of polythene when creating packaging solutions in the future.