Ultimate Buying Guide for Remesh in UAE

Are you ready to build your next project? Remesh, also known as wire mesh, is a construction workhorse you'll likely need for most constructions. But how do you select the right remesh product and where to buy it in the UAE? This guide cuts through the confusion to help you navigate the different types, specifications, and uses of remesh.

What is Remesh, and Why is it Popular?

Think of Remesh as woven metal fabric. It's like a wire grid. The cool thing about remesh is it's super flexible. It's made from stainless steel, mild steel, aluminium, or copper. It's awesome for lots of other jobs. Here's why:

- It's tough: Need something that can take on heavy stuff? Remesh has your back. It's super sturdy and perfect for hard tasks.

- It's bendy: Remesh is tough but still flexible. It can be shaped to sort out any project you have.

- It lets air and light in: Sometimes, you need a material that won't block air or sight. Remesh has you covered. Its tiny holes allow air and some visibility.

- It's affordable: Are you trying to save some cash? Remesh is usually a better bargain than other materials, so it's a top choice for many jobs.

Types of Wire Mesh

Do you know about remesh and its superpowers? Let's break down the usual types of wire mesh we can find in the UAE and their special features and uses:

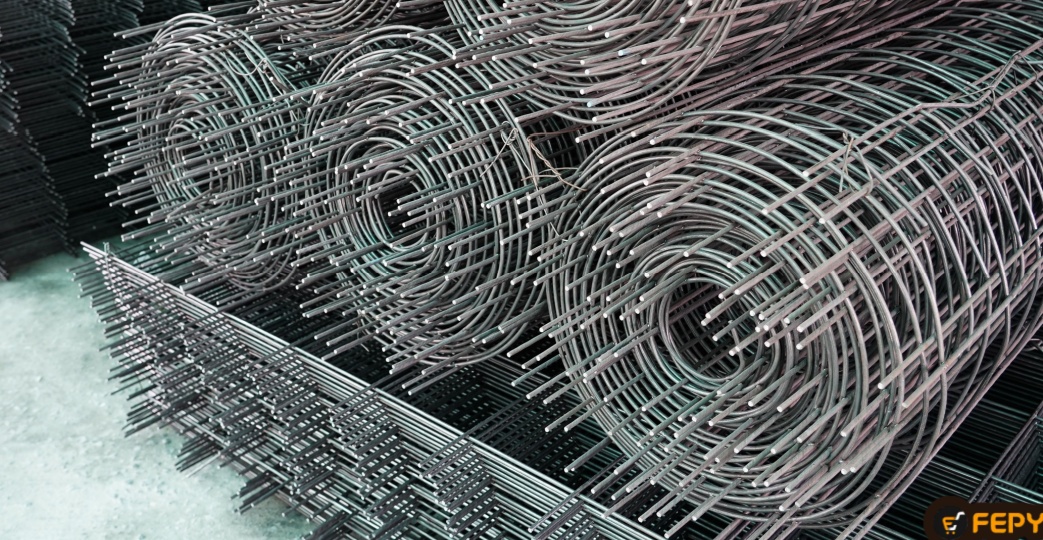

1. Welded Wire Mesh:

Think of a metal grid that's a welded wire mesh. Wires get fused at meeting points, making a strong, long-lasting mesh. This toughie is hard to rust and can withstand wear and tear. It's perfect for construction projects like fences, cages, racks, and grates.

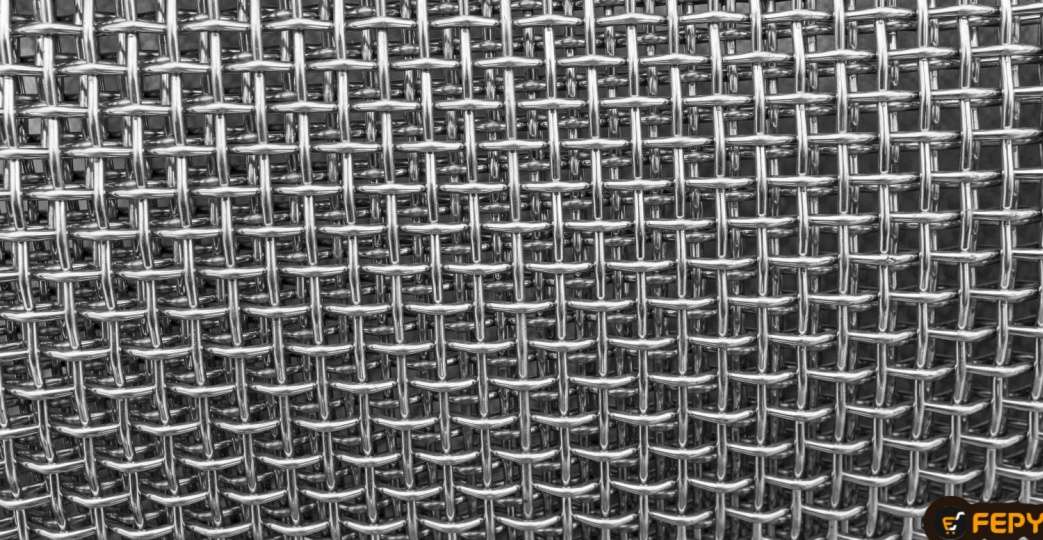

2. Woven Wire Mesh:

If you need precision, this is your mesh. Woven wire mesh is created by weaving wires in a specific pattern. The result is precise: exact mesh count, wire diameter, and aperture size. It's just what you need for tasks requiring precision, like filtering, sifting, and screening.

3. Crimped Wire Mesh:

Have you got a big job? You need crimped wire mesh. The name comes from the crimping process, where wires are twisted before weaving, resulting in a stronger and more durable mesh. If you're in heavy-duty industrial work where toughness is important, this is the mesh you need.

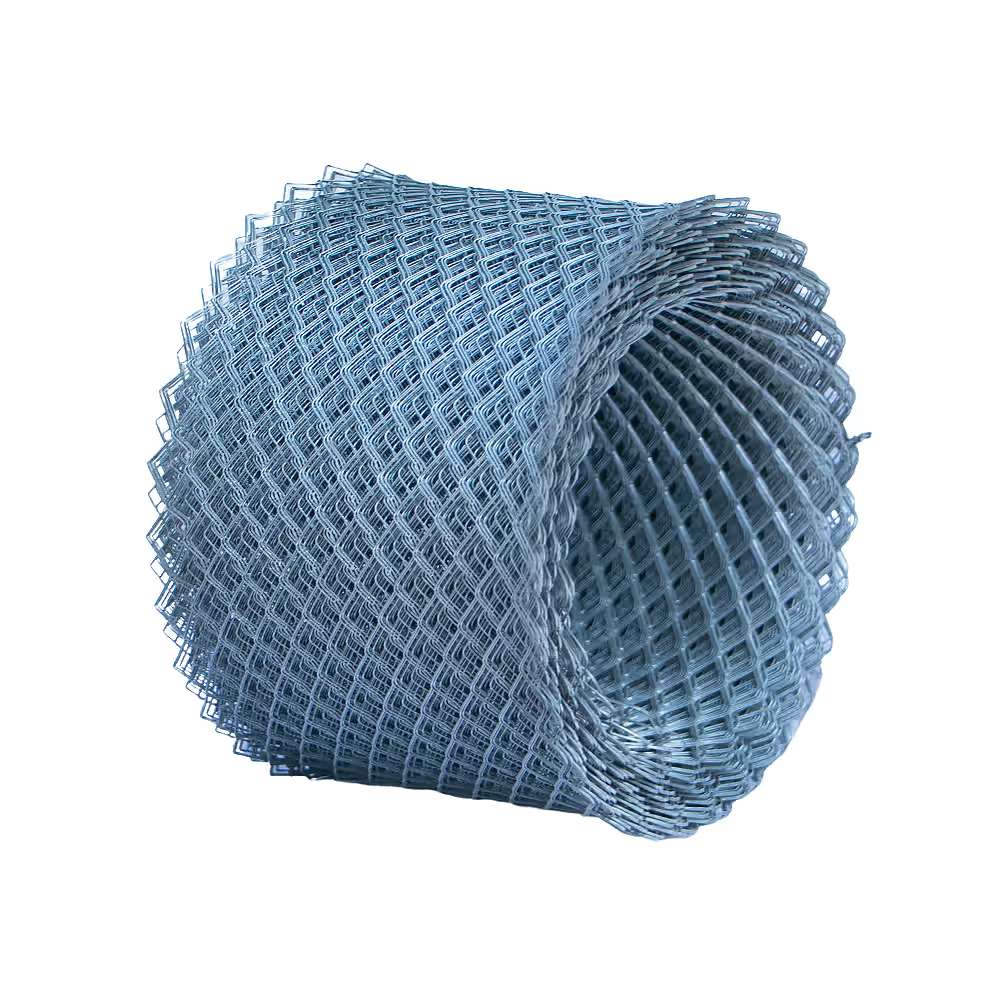

4. Galvanized Wire Mesh:

Rust is a big enemy! Galvanised wire mesh fights it with a protective zinc layer that stops corrosion. You can apply this treatment before or after welding. Because it resists rust so well, it's used in many areas, such as farming, building, transportation, and mining.

5. PVC-Coated Wire Mesh:

This mesh is practical but also stylish. A thin PVC powder layer makes it durable and weather-resistant. Plus, you can choose from different colours! It's great for projects where looks are as important as rust resistance.

6. Stainless Steel Wire Mesh:

This mesh is a super fighter. Made from high-grade stainless steel alloy, it's strong, resists corrosion, and lasts. It's perfect for tough conditions and demanding applications, such as chemical processing, food processing, and pharmaceutical manufacturing.

7. Vinyl Coated Wire Mesh:

Like PVC, vinyl-coated wire mesh offers rust resistance and style. The vinyl coating is long-lasting, weatherproof, and comes in different colours, making it great for projects that need to be functional and look good.

8. Dutch Weave Wire Mesh & Twill Wire Mesh:

These weaves are all about precision. Dutch and twill weave creates precise meshes, perfect for tasks that require accuracy. Filtering and sieving tasks heavily rely on these detailed weave patterns.

9. Plain Weave Wire Mesh:

Sometimes simple is best. Plain weave wire mesh has a basic weave pattern, perfect for filtering and sifting tasks. It's a practical choice for tasks needing precision.

Remesh Specifications

Now that you know the different types of remesh, it's time to understand their specifications! These little details decide which remesh is right for you and your work, ensuring it does the job well and for a long time. So, let's break down the big specs:

1. Mesh Count:

Think of a square inch of wire mesh. Mesh count is how many holes are in that square inch. Both ways are counted, up and down, left and right. So, if there are ten holes each way, it's a 10 x 10 mesh. Or, in simpler terms, Number 10 mesh.

Aperture Size refers to the space between wires next to each other. It's normally measured in millimetres and is connected to the mesh count—the smaller the aperture size, the higher the mesh count.

2. Wire Diameter:

This is like your remesh's backbone - the thickness of the wires in the remesh, measured in millimetres. The thicker the wire, the lower the mesh count. However, thicker wires also make for a stronger mesh.

3. Open Area Percentage:

Have you ever wondered how to open your remesh? The answer lies in this percentage. It especially points out how much of the mesh allows air, light, and you to see through it. So, the higher the rate, the more open the mesh!

4. Weight per Square Meter:

This tells you how heavy your remesh is. It's calculated in kilograms per square meter, and it sets out the total weight of the mesh over a certain area. It's an important detail if the weight matters for what you're doing.

5. Material:

What makes up the wire mesh changes. It might be stainless steel, light steel, aluminium, copper, or other mixes. Each one is good for some things but not great for others, depending on their needs.

6. Weave Type:

Different wire arrangements give meshes unique qualities. Plain styles are nicely balanced, and twill styles are especially durable. Crimped styles are great for tough jobs. Understanding wire styles helps you choose the best mesh for your needs.

7. Pitch:

This term refers to the hole size and wire thickness. It's noted in millimetres and helps figure out the mesh count.

8. Warp and Weft Wires:

Consider the mesh like a piece of cloth. Warp wires align with the roll length, while Weft Wires stretch across the width. This info aids in setting mesh sizes and shows how weight spreads across the mesh.

9. Crimp Pattern:

Only relevant to crimped wire mesh, it's about how wires are turned before weaving. This turns the dial on mesh sturdiness and bendiness.

10. ASTM Specifications:

For an added layer of assurance, check ASTM specifications. The American Society for Testing and Materials offers these rules to ensure the mesh matches particular quality and performance markers. Like, ASTM A-1064 works for welded wire mesh used in buildings.

11. EMC Considerations:

Study the mesh's EMC features if your project involves managing electromagnetic suitability (like ensuring shielding effectiveness or EMI worries). You may need this for electronics or delicate machinery projects.

Remesh Applications

Let's look at the different types of remesh teams and their useful applications. Remeshs is a multi-tasker that fits into many industries. Here's a peek into how it's top applications:

1. Water Filtration Systems

Think about crystal-clear, drinkable water. Here, remesh can do wonders. It filters unwelcome particles out of the water, ensuring we get the best. It makes it an MVP in water treatment centres where water quality is most important.

2. Partitions and Enclosures

Need to create secure and durable partitions or enclosures? Remesh steps up to the plate! In factories, warehouses, and even farms, remesh acts as a reliable barrier, separating areas or containing materials. Think crop protection, support structures for climbing plants, or securing livestock – remesh handles it all.

3. Animal Enclosures and Agriculture

From keeping livestock safe and secure to providing fencing that deters pesky critters, remesh champions animal well-being and agricultural success. Often galvanised or coated to fight rust, remesh ensures animal enclosures and agricultural fencing are built to last.

4. Reinforcement in Construction

In the world of construction, remesh is a trusted ally. Used to reinforce concrete structures, it significantly boosts their load-bearing capacity and overall strength. Imagine a hidden web of support—that's remesh. It ensures buildings distribute weight evenly and resist weaknesses, leading to longer lifespans.

5. Industrial Applications

Remesh is fearless in getting its hands dirty in various industrial applications. It plays a key role in conveyor belt systems, allowing for airflow and drainage—crucial for transporting materials that need ventilation or avoiding water damage. Mining, construction, and bulk material handling all rely on Remesh's industrial prowess.

6. Pest Control

Keeping Pests at Bay: Do you have unwanted visitors in your home or garden? Remesh comes to the rescue! Used in fencing and screens made from stainless steel or galvanised steel, remesh is a formidable barrier against pests and rodents.

7. Kitchen Utensils

Remesh is found in various kitchen utensils, from trusty strainers to handy baskets. Its durability and easy cleaning make it a popular choice for all your filtering and containing needs in the culinary world.

8. Outdoor Activities

Bird feeders, flowerbed edging, and even chicken coops – remesh adds functionality and style to your outdoor activities. Often galvanised or coated to fight rust, it ensures your outdoor creations are weather-resistant and long-lasting.

9. Fire Safety

Remesh steps up for fire safety, too! Fireplace screens made from stainless steel or other heat-resistant options utilise remesh to prevent sparks from escaping and provide essential heat control.

10. Medical and Pharmaceutical Applications

Remesh plays a crucial role in medical and pharmaceutical applications. Used in filters and screens, it helps separate and purify materials – a vital function for ensuring the highest standards in these critical fields.

10 Key Factors to Consider When Buying Remesh in the UAE

Now that you've explored the different types and applications of remesh, it's time to navigate the buying process. Here are 10 key factors to consider when selecting the perfect remesh for your project in the UAE:

1. Product Type:

Remesh comes in two key types - woven mesh and welded mesh. Woven mesh, made by weaving wires together, shines in adaptability. Imagine building facades, ornamental screens, and railings. On the other hand, welded mesh, created by bonding wires at cross points, gives top-notch toughness. It's great for heavy-duty jobs.

2. Material:

Choosing the best material is crucial for your project. Let's explore some popular options:

- Stainless Steel: Known for being super resistant to corrosion, stainless steel is perfect for applications requiring high performance and durability, such as chemical processing or food manufacturing.

- Brass: Want some sophistication? The brass wire meh, only available in a woven style, is a preferred choice for decoration.

3. Mesh Count, Wire Diameter, and Opening Size

Think of Mesh Count like holes in a line of inches. More holes mean smaller wires and tinier gaps, perfect when you need precision.

Wire Diameter is the thickness of the wires. Yes, the thicker they are, the stronger they become. But they may struggle in jobs that require them to bend.

Opening Size is the distance from one wire to its neighbour. The smaller the gap, the greater the total mesh count. These are generally chosen when exactness is needed.

4. Weave Type and Pattern

The way the wires are woven creates distinct characteristics. Knowing these patterns helps you pick the perfect mesh for your task. Meanwhile, welded mesh uses a solid grid pattern bound together for toughness.

5. Customisation

Some suppliers offer customisation options, such as cutting to size, shaping, welding, or edging. These can be game-changers if you need a specific size or form for your project.

6. Certifications and Standards

Look for suppliers prioritising quality by adhering to industry certifications and standards, like ISO 9001 (quality management) or AS9100 (aerospace quality). These certifications assure you that the remesh meets established benchmarks.

7. Availability and Services

Time is of the essence! Ensure the supplier has the exact kind and amount of remesh you need at the right time. Consider cutting, shearing, or welding to your specs for services. Does that sound handy? Loads of suppliers provide making services, so your remesh is set for action.

8. Industry Experience

Experience is a valuable asset. Seek out suppliers with a proven track record in the industry. Their knowledge can guide you towards cost-effective solutions that perfectly match your project's needs.

9. Price-Quality Balance

Comparing costs among various suppliers for the best offer is normal. But remember, the quality must be preserved. A less expensive alternative may not meet your needs in terms of performance or longevity. For quality, seek suppliers known for their superb remesh that matches your requirements. A well-made product means a lasting investment.

10. Research and References

Always look before you leap! First, scout the web for details about the provider and their goods. Read feedback and tales from folks who have engaged them before. This will give you a solid feel of who they are and what they can do.

Next, there's no harm in inquiring about other satisfied customers. Getting input from people who've bought that supplier's remesh before will let you gauge their dependability, customer satisfaction, and the standard of their products.

FAQs

What are the different types of remesh available in the UAE?

The UAE's remesh squad boasts three main members: woven wire mesh, welded wire mesh, and expanded metal mesh. Each offers unique strengths, making them suitable for a variety of applications.

How do I choose the right mesh count, wire diameter, and opening size for my needs?

Choosing the Perfect Mesh Trio: Mesh Count, Wire Diameter, and Opening Size is crucial. This dynamic trio depends on your project's specific needs. Higher mesh counts and smaller openings are ideal for precision tasks, while thicker wires offer superior strength but less flexibility.

What materials are commonly used for remesh in the UAE?

Stainless steel is the most popular material due to its high strength, corrosion resistance, and durability. Mild steel offers a cost-effective option, while aluminium and copper have specialised uses.

How do I ensure I'm getting high-quality remesh?

Look for suppliers with certifications like ISO 9001 and positive customer reviews. References from past clients can also provide insight into a supplier's quality and reliability.

What customisation options are available for remesh in the UAE?

Some suppliers offer customisation services, such as cutting to size, shaping, welding, or edging. This can be a game-changer if you need a specific remesh form for your project.

What are the benefits of buying remesh from a reputable supplier in the UAE?

Reputable suppliers guarantee high-quality remesh that meets your exact requirements. This translates to long-lasting performance, reducing the need for replacements and saving you money in the long run.

Final Words

You're now prepared to master remesh buying in the UAE, thanks to this easy-to-follow guide. You've learned about the various kinds, made sense of the specs, and discovered the many uses of remesh.

It's essential to consider quality, durability, cost-effectiveness, and maintenance. Considering these factors, you'll make wise buying choices that accurately match your project's requirements.

Always buy remesh products from FEPY, the leading e-commerce store in the UAE. You can check out the comprehensive collection of products and choose the one that best suits you. If you buy in bulk, you will get great discounts. Feel free to call the FEPY helpline for more details.